TRON Bike 17 Feb 5:56 AM (8 months ago)

Model of a fictional motorcycle from the “TRON: Legacy” movie. Features drive, steering and custom lighting.

Datasheet:

Completion date: 06/11/2024

Power: electric (BuWizz 2.0)

Remote control: BuWizz 2.0

Dimensions: length 37 studs / width 15 studs / height 20 studs

Weight: 0.686 kg

Suspension: none

Propulsion: 1 x RC buggy motor from outer output on the rear wheel

Motors: 1 x RC buggy motor, 1 x PF Servo

I have already built an RC model of the TRON bike back in 2016, but it looked all wrong, with terribly miscalculated proportions, and it only drove thanks to tiny wheels hidden under the big, fixed wheels. But ever since LEGO has introduced 11 x 11 round liftarm rings, I felt like maybe I can build properly working TRON bike with these. And it took me a while, but I got there eventually.

The bike was modelled as close as possible after the bike shown in the 2010 “TRON: Legacy” movie and because my 2016 model used blue lighting, this time I went with orange one. I started by trying to put the 11 x 11 rings inside a 94.3mm D. x 38mm Motorcycle Racing Tread tire, which looked pretty cool but drove pretty poorly. The issue was the poor fir between the rings and the tire, with gaps that caused the tire to wobble around the rings and which made actually driving such a wheel tricky. In short, the only reasonable solution at this scale was to have a small wheel pressed to the outside of the tire, driving it, but because of the gaps it was necessary to press it with a lot of force, which in turn increased friction, made the wheel harder to rotate, and required pressing it even stronger.

While trying to come up with a better solution, I reached out to my friend Rob who runs Brickstuff and continually develops all sorts of LEGO-compatible lighting products, to see if he had an idea of how to illuminated the wheels of the model. It seemed to me that the best approach was to use long 3mm rigid LEGO hoses, bent to form nearly complete circles, but I didn’t have any way to light these hoses up. Rob came through, as he always does, and delivered identical hoses with LED filament inside, that could be built to specific length and lit up at specific color.

With the lighting solved, I went back to building the wheels. It was my goal to make the wheels work as closely as possible to the “real” ones, and in the schematics from the movie it can be seen that the “real” bike uses three-piece wheels. There is an inner roller ring, then there is a very thin tire rotating around it, and then there is a housing that covers the tire entirely from all sides, except for a small cutout at the bottom, which is where the tire comes in contact with the ground. I wasn’t sure I can build a good-looking LEGO housing around a tire at this scale, but I wanted to at least have a thin tire rotating around a fixed ring.

Eventually I found that if I build the ring from 6 x 6 curved gear racks, the holes on the side of this ring will have different spacing than holes on the side of the 11 x 11 ring – a spacing that will allow me to use half-pins to attach the 6 x 6 x 2 round corner brick quite securely to the resulting ring. Both of these pieces were available in black, and together they formed a nice, rounded wheel that looked pretty close to the wheels seen in the TRON movie. The only issue was that the resulting wheel was almost completely smooth on the outside, with barely any attachment points, so in order to keep it securely attached to the chassis, I have covered 3/4 or the ring with round bricks and kept 1/4 free to access the pin holes in the ring.

Now, there was a 3-studs-wide, shallow groove running around the outside of the wheel, between the round bricks on one side and the other. I’ve tried putting a number of elements inside that groove, including a LEGO chain which was too thin to protrude outside of the diameter of round bricks on the ring, and I was just about to drop this idea when it occurred to me that a LEGO 3-studs-wide track may not be of the same height as the chain, despite being closely related to it. And this turned out to be true – when I wrapped that track around the ring, the outer diameter of the track was marginally larger than diameter or the round bricks on ring’s sides, allowing the track to protrude out of the groove and touch the ground below the wheel. This also made driving the wheels quite trivial – I simply wrapped a shorter section of track loosely around the front wheel’s ring, and then a longer section of track around the rear wheel’s ring AND a gear wheel, so that the gear wheel meshed with inside of the track.

Steering the front wheel was a little tricky because the ring had pin holes facing only to the sides, not up or down, so I couldn’t pivot it around a vertical axle. Instead, I attached a system of parallel levers to the sides of the rings, creating a virtual pivot that was operated by a vertical PF Servo motor. I’ve also managed to fit an RC buggy motor to drive the rear wheel’s track and to squeeze in a BuWizz 2.0 to power the whole model The lighting system of the wheels was powered from the BuWizz too, using a regular Power Functions plug, and so was the Brickstuff LED beacon that I managed to fit on one side of the bike (the other side had the RC motor in that spot).

The resulting model looked way more accurate than my 2016 attempt, it was able to drive and steer, and the illumination looked great. The traction was an issue because the tracks had contact with the ground over a very limited area, and the stability wasn’t that good – the bike had a tendency to flop to a side when trying to turn at high speed. But it drove just fine on a carpet, and in fact was quite fast in a straight line on it.

Due to the fairly low scale, the model’s body looked way more blocky than it shoud have, and was missing inward curves seen in the original bike simply because these would expose the motors, the BuWizz and the internal mechanisms. It also took me a while to build the “roof” that’s supposed to cover driver’s back, because it had to be rigid, curved and very thin. I’ve played around with 3mm hoses kept bent by a string, but I was eventually able to build it using hinge plates with fingers.

Work in progress photos:

Photos:

Video:

Kettenkrad 17 Feb 5:09 AM (8 months ago)

Model of a German WW2 half-track motorcycle. Features drive and steering with an automated braking system.

Datasheet:

Completion date: 20/10/2024

Power: electric (Circuit Cubes)

Remote control: Circuit Cubes

Dimensions: length 22 studs / width 8 studs / height 12 studs

Weight: 0.265 kg

Suspension: none

Propulsion: 2 x Circuit Cubes regular motor

Motors: 3 x Circuit Cubes regular motor

The Kettenkrad, or Sonderkraftfahrzeug 2, as it was formally called, was a legendary WW2 German vehicle because of its uniqueness. Designed as a light tractor for airborne units, it combined front wheel of a motorbike with tracks of a small tank. It was known for its reliability and cross-terrain capability, but also for its complex steering system which worked like a regular front wheel of a motorcycle to a certain point, but when the handlebars were rotated beyond that point, the track on the inner side of the intended turn would get brakes applied to it automatically. I was interested in re-creating this steering system in a LEGO version, and after noticing that the Kettengrad’s road wheels look very much like LEGO wedge belt wheels, I set out to build a model scaled to these wheels.

The wheels dictated a very small scale, with a 7 studs wide chassis and with tracks being just 1 stud wide each. I have used LEGO chains for tracks and – since the LEGO power supplies and motors were far too large here – turned to Circuit Cubes in order to power the model and control it remotely.

I have succeeded in building an automated steering system that produced similar result to the real one, although without using brakes. In my model, the tracks were driven via two separate LEGO transmission driving rings, with each ring being kept engaged by a rubber band. Once the handlebars would get rotated sufficiently far, the bumps on them would press on a slider on the inner side of the turn, disengaging the corresponding driving ring and thus disconnecting the track on this side from the drive motor. Once the handlebars returned closer to the central position, the rubber band pushed the slider back and the ring was engaged again, driving the track just like before.

On the aesthetic side, the model looked pretty, and I mean pretty terrible because of being entirely filled with mechanisms (16 gear wheels total). I was able to keep the chassis 7 studs wide, but in order to fit everything in, I had to make the model about 1 stud taller than it should have been. The bodywork was also extremely fragile and the drivetrain wasn’t much stronger. To make things worse, the front section of the tracks didn’t touch the ground because I have built the chassis first with a smaller front wheel, which I then replaced with a more accurate, larger one, and adjusting the chassis for the difference in their sizes would make the front of the model even taller. The final front wheel used the LEGO 30.4 x 14 VR tire, which I found to be exceptionally soft, pulled over a LEGO large steering pulley. This worked quite well and the tire wasn’t damaged or misshapen as a result.

As for the performance, the model was very slow because there was only one gear ratio that fit inside the chassis, and it suffered from low traction – so low, that when I attached a trailer with a GoPro camera on it to the model, it was unable to pull it. But the steering system worked flawlessly and efficiently – in fact, it was very responsive to even slight motions of the handlebars, even before one track or the other would get disengaged.

Photos:

Video:

XM376 17 Feb 4:39 AM (8 months ago)

Model of an experimental US Army truck. Features 8×8 drive, steering, 2-speed transmission and 2-stage suspension.

Datasheet:

Completion date: 23/09/2024

Power: electric (Power Functions)

Remote control: SBrick

Dimensions: length 69 studs / width 28 studs / height 29 studs

Weight: 2.873 kg

Suspension: 2-stage double wishbone dependent

Propulsion: 4 x PF L motor via a 2-speed transmission (1st speed gear ratio: 16.2:1, 2nd speed gear ratio: 5.4:1) on all wheels

Motors: 4 x PF L, 1 x PF M, 1 x PF Servo

This model was a follow-up to my MAZ-535 model from 2019. I was unhappy with MAZ’s performance, especially with its overengineered pendular axle suspension, and I wanted to use new types of LEGO pieces to improve on it. To that end, I kept looking for a short 8×8 off-road truck with good approach and departure angles, but most of the trucks of this kind are Soviet-made and for the time being I wanted nothing to do with Russia. Eventually I stumbled upon this rejected project for US Army, which was interesting but extremely limited when it comes to available documentation.

The XM376 and XM377 were two parts of a single transport solution submitted to US Army in 1957, with the goal of facilitating transportation of tanks over rough terrain. The idea was that these two 8×8 heavy-duty off-road trucks would be connected by a suspended trailer with a tank resting on it. To make this work, the truck at the rear – the XM377 – had its cabin rotated front to back, facing towards the trailer rather than away from it. The whole setup was operated by two drivers, one in each truck, coordinating over radio. The project was rejected after field trials which proved that the trucks with the trailer weigh almost 3 times as much as the tank itself, need more fuel than the tank does, and require enormous amounts of free space to maneouver. It appears that there was only one of each trucks made and that they were both scrapped some time later, with very little documentation left. In fact, all I was able to find were three photos.

Unlike my MAZ-535, the model was built with double wishbone suspension, utilizing the wheel rims introduced in the 42110 Land Rover Defender set to reduce its width. In order to increase the suspension travel and make the suspension more responsive, I didn’t use the regular independent wishbone suspension setup where each wishbone is supported by a shock absorber connected to the chassis. Instead, my model had each wishbone supported by a shock absorber connected to the shock absorber of the corresponding wishbone on the opposite side (left/right). This allowed the suspension to work in two stages: one stage where wheels moved by raising on one side and lowering on the opposite side without compressing the shock absorbers, and second stage where the shock absorbers would get compressed. This resulted in a significantly increased suspension travel, because it wasn’t limited by the shock absorber’s range of compression, and in increased responsiveness, because the wheels could react to loads that were too small to compress the shock absorbers. The downside was inferior sideways stability – with a center of gravity sufficiently high above the ground, it was possible for the chassis to tilt left or right due to the lack of rigid connection between the wishbones and the chassis. Because of that, it was my goal to keep the center of gravity as low as possible, and I ended up squeezing almost all mechanical and electrical stuff between the axles. The only things that were located above the axles were the motor controlling the steering, the motor controlling the transmission and a single SBrick.

As shown below, the steering system was located between axles #1 and #2, the transmission – between axles #2 and #3, the propulsion motors – between axles #3 and #4, and the single battery box was installed behind axle #4 to counteract the weight of the cabin. In fact, thanks to the new pieces such as the 3×19 liftarm frames, the whole suspension was impressively compact and almost everything above the wheels was empty body shell, which was a huge improvement over the MAZ-535 model.

The propulsion consisted of 4 hard-coupled PF L motors powered from a single battery box, but using the high-powered Ni-Zn batteries. These drove a 2-speed transmission operated by a PF M motor, producing 3:1 and 1:1 gear ratios internally, which – combined with the planetary wheel hubs – resulted in final gear ratios of 16.2:1 at the lower gear and 5.4:1 at the higher one. All four axles were driven using knob gears instead of differentials.

As for the look of the model, I could only see two sides of the truck on the photos I found, so plenty of details had to be made up. There were no blueprints, so I had to use my best judgement for the proportions, but I think the end result looked good enough, except for being clearly to tall to account for the increased suspension travel.

In terms of performance, the model turned out to be a disappointment. It turned out that after about 1 hour of test-driving in rough terrain the driving ring in the transmission got so worn that it would disengage under stress, even though it was firmly kept in place by the rotary wave selector. It’s possible that the 24t clutch gear which was engaged by this ring at lower gear was also at fault. All in all, it was obvious that the transmission couldn’t handle the torque and there was no easy solution to this other than adding extra gear reduction between the transmission and the wheels, or removing the transmission entirely. There was also one incident of the 16t gears by the PF L motors collecting so much grass and dirt that the motors were stalled. Luckily, it was easy to detach axle #4 and clean the gears, which resolved the problem. While the PF L motors never stalled except for this one case, it was my impression that if I used PF XL motors instead, they would simply grind through any grass without stopping. And while the single battery box with six Ni-Zn batteries kept powering the motors at all times without stopping, it was my impression that it was getting hot and that the overall performance degraded over time when operated outdoors in hot sunny weather.

The model proved a valuable lesson. It was a marked improvement over the MAZ-535 model in several areas, such as compactness, chassis rigidity and suspension responsiveness, but just like the MAZ, it suffered from transmission problems.

Photos:

Video:

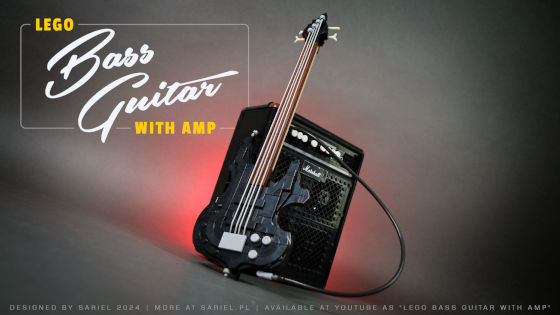

Bass Guitar 17 Feb 3:07 AM (8 months ago)

Model of a bass guitar inspired by ESP F-104, with an amp based on Marshall MB4410.Free building instructions available

Datasheet:

Completion date: 30/05/2024

Power:none

Remote control: none

I was quite excited to see LEGO releasing the 21329 Fender Stratocaster set back in 2021. I loved the idea as well as the execution and it seemed to me only a matter of time until LEGO followed with more guitar sets, seeing how many various and iconic guitars are out there. But by 2024 there were still no news of a follow-up set of any sort, so I’ve decided to try submitting my own guitar model to LEGO Ideas, and being a bass player (or wishing to be one, at least), I went with a bass guitar model closely based on my own ESP LTD F-105, except that I used four strings to make the guitar look more like a regular bass guitar, which effectively made it a model of the ESP LTD F-104. I’ve paired that guitar with a model of an amp that I’d love to own but can’t afford, that is Marshall MB4410.

Sadly, LEGO Ideas being LEGO Ideas promptly rejected my submission stating that it “overlaps with the 21329 Fender Stratocaster set”. Meaning, in other words, that they won’t accept any guitars whatsoever because a single LEGO guitar set already exists. This is obviously a very logical decision, comparable to not allowing any cars because LEGO already makes cars, or any buildings because LEGO has released one or two of these already. Seriously, I hope this was actually a preventive measure as LEGO is preparing to release a line of guitar sets of its own, but it remains to be seen whether that will be the case.

Both the guitar and the amp were built without using blueprints, just by eyeballing the real objects. The thing I didn’t like about the LEGO Stratocaster set was the 2-studs-thick guitar body which just looked too thick to me, so I made it my goal to keep my guitar thinner. To this end, the body is built using a single layer or bricks with two layers of plates on the front, making it 1 and 2/3 studs thick, which isn’t much less than 2 studs, but using plates on the front allowed me to sculpt the edges of the body. These edges are tapered in the real ESP guitar, and by making the plates not reach all the way to the edges I was able to at least remotely approximate that tapered edge look.

My other goal was to keep the guitar’s neck accurately shaped. In the LEGO Fender set, the neck had a square cross-section, being built of layered plates, but the correct shape is rounded on the bottom, which I achieved with curved slopes and inverted tiles. That makes my guitar’s neck more fragile than Fender’s, but actually not by much.

The amp was essentially an empty box – I didn’t feel the need to build the inside too, like in the LEGO Fender set, because it didn’t seem that important and because I had no clue what the inside of the real amp looks like. One functionality I was able to include was a cradle switch in the amp activating a light brick that illuminated a red “LED” on the amp’s front panel.

Free building instructions for the guitar and the amp are available here.

Photos:

Video:

Mad Max Big Foot 17 Nov 2024 12:46 PM (11 months ago)

Model of a vehicle from the “Mad Max: Fury Road” movie. Features 4×4 drive, steering, V8 piston engine, motorized radiator fans and crawler-type suspension.

Datasheet:

Completion date: 08/05/2024

Power: electric (Control+)

Remote control: Control+

Dimensions: length 44 studs / width 34 studs / height 38 studs

Weight: 2.268 kg

Suspension: 3-link triangulated

Propulsion: 2 x C+ XL motor geared 10.8:1 on all wheels

Motors: 2 x C+ XL, 1 x Mindstorms M, 1 x WeDo 2.0 M

This project was started by pairing LEGO Power Puller wheels, which are known for their enormous rolling resistance, with planetary wheel hubs to see what kind of performance can be achieved. It looked promising, so I added crawler-like 3-link triangulated suspension and proceeded to build a model of the Big Foot vehicle from the “Mad Max: Fury Road” movie, a movie that put plenty of vehicles on my “wish I could build it one day” list. In fact, I have already build a model of the Peacemaker vehicle from the same movie back in 2015, so another vehicle seemed long overdue.

The Big Foot was relatively simple on the mechanical side, but quite challenging aesthetically. The chassis was in essence a standard monster truck chassis with 4×4 drive and 3-link triangulated suspension in front and back, and the only challenge was making it short enough – a challenge I didn’t quite manage, making the chassis around 10% longer than it should be in order to be able to connect the driveshaft to two drive motors. This was fortunately mostly covered up when near the completion of the project I switched from LEGO Power Puller tires to slightly larger third-party tires, whose size brought the front and rear axle closer together, at least visually. Steering was handled by a Mindstorms M motor directly, without gearing but via a CV joint that turned out to have an unfortunate tendency to fall out and get lost in the sand. Finally, because the outputs of the drive motors were located at the very bottom of the chassis, I’ve used a separate WeDo 2.0 M motor to run a V8 piston engine with a fan under the hood, along with two fans in the back. I had to use pulleys and belts to fit this motor inside the cabin, but that proved to be actually quite useful, as the belts acted as slip clutches in case the engine or the fans got jammed.

On the visual side, the primary challenge was insufficient documentation – there was not a single blueprint of the body, for instance. I found that the bodywork was based on the 1940 Didge Fargo, but just like with other vehicles built for the movie, it has been extensively modified, stretched and chopped up so that it ended up being nowhere near the dimensions of the original car. In fact, there was not one but two Big Foot vehicles built, one for high-speed sequences and one for close-up shots, and the were both build on regular monster truck chassis, but the action scenes got so intense that one of the cars actually got its body frame broken. It was also difficult to see all the details, for instance where it came to armament. For some reason the harpoon gun is shown in the movie front end center while the flamethrower is almost always obstructed by something or someone. Going through the movie scene by scene I found just a single scene, lasting less than 1 second, where it was shown close from a side. Some details were so small that I chose to omit them, such as pieces of dolls merged into the rear bumper, which can be barely seen in the movie and which would simply not be identifiable if built with LEGO pieces at this scale.

The bodywork required complex STUD techniques, especially in the front where I had to build large curved grille with a big rotating engine fan right behind it, and then there was the hood which had to be carefully shaped, thin enough to fit over the big engine and strong enough to be opened. I’ve decided to not make doors open, because there was no interior to see in the cabin, just mechanisms, and also because with that much snow the structural integrity of the body wasn’t great and having solid doors helped to keep the front and rear firmly together. The Control+ hub was located at the back of the cabin, with the indicator LED visible through a trans-clear roof section and it was possible to replace the batteries without destroying the body. The space inside the body directly behind the hub was hollow and only covered with tiles from the top. It was normally used to store excess cables, but when needed, the tiles could be taken off, the cables pulled aside and that created enough room to take the batteries out of the hub.

From the start, the model was being built with the LEGO Power Puller wheels installed, but towards the end of the build I came across third-party monster truck tires that could fit the same rim and decided to use them due to their more accurate shape and truly massive size.

To film the model, I have purchased tan and blue-colored paper backdrops but in the end I didn’t need them. I found an open sand mine not far from where I live and I was able to take the model there during a holiday period and film it. It was quite a spectacular location and I hoped that I’ll be able to use it again in the future.

Work in progress photos:

Photos:

Video:

Cycle of Life 17 Nov 2024 7:11 AM (11 months ago)

A small project created as submission to the LEGO Ideas “Picture Perfect Memories” activity.

Datasheet:

Completion date: 05/02/2024

Power: manual

I’ve never participated in a LEGO Ideas challenge, until I came across the Polaroid-themed “Picture Perfect Memory” challenge. The objective was to build any scene viewed through a photo frame of predefined dimensions.

Now, I have a massive appreciation of the short film “Last Day Dream” shot by Chris Milk back in 2009, which you can see here. It gave me the idea of showing not a single scene but a series of scenes together forming a whole. Going through the challenge rules, I found that a single frame was a requirement, but there was nothing about how many scenes can be viewed through it and nothing saying that the scene couldn’t involve moving parts. So I’ve come up with an idea of having the photo frame with several scenes behind it installed inside a drum that could be rotated from one scene to the other at the press of a button.

As for the content, being a parent I thought about showing how my experiences with my children reflect my experiences with my parents; or, more broadly, how one starts seeing a certain pattern – a cycle, if you will – when you compare your experiences of having a parent and of being a parent yourself. Thus, I’ve decided to build a series of scenes that show the beginning and end of parenthood, and to make the scenes readable despite their small size, I’ve chosen to limit the number of participants to just one parent with one child. And since the scenes had to deal with the passing of time, I chose to pair a father with a daughter in order to make it clear that these are two different people and not a younger and older version of the same person.

Thus, the idea for a “cycle of life” series of scenes was born, with 6 scenes total, as 4 seemed too few and 8 – too many. On the mechanical side, I’ve adapted the stepper mechanism from the LEGO 42083 Bugatti Veyron set, modifying it to perform 6 steps per full rotation rather than 4. The stepper served as a base on which I installed a drum built around the 6-sided Technic rotor plate piece. That created enough room for 6 small “boxes” with 5 sides each, so each of them could have different floor, ceiling and walls, and enough room for two minifigures inside. The whole thing was rotated 1/6th of full rotation at the press of a button. It crossed my mind that it might be cool to make the button look and work like a camera shutter release button, but I was running short on time and frankly, my hopes at winning weren’t great due to the sheer amount of other submissions (over 600).

The scenes dealt with cycle of parenthood in a father-daughter relationship. They start with a young man becoming a father in a hospital room, then there’s a dad playing with daughter on a swing, a dad attending his daughter’s graduation ceremony, an elderly father attending his daughter’s wedding, a dad visiting an accomplished (and pregnant) daughter at work, and finally the daughter welcoming her own child in a scene that mirrors the first scene and also implies that the her own father is gone at this point.

I put quite a lot of work into the minifigures and the details of each scene. The dad was quite a challenge, as he had to visibly age by some 50-ish years, step by step. I found the daughter easier to work with, as I basically had to use a baby, a child, and then a woman going from early adulthood onwards. The details in the scenes, while small, called for a lot of work – for instance, the first and last scene feature similar hospital room but with considerable amount of time passing between, so I’ve tried to make the latter scene look observably more futuristic (e.g. changing the look of the clock present in both scenes). It was also my goal to have distinctly different floor in each scene, and many scenes included additional structure, such as a partial tree and foliage, or a scene with simplified representation of an audience behind it.

The submission didn’t win anything, but it was an interesting, unique build for me, and the subject proved unexpectedly emotional and thought-provoking to me.

Photos:

Video:

Dot Matrix Clock 1 Jul 2024 6:09 AM (last year)

A Mindstorms clock using axles and pin holes as a grid dot display.

Datasheet:

Completion date: 31/01/2024

Power: electric (Mindstorms brick)

Language: Scratch

Bricks: 1

Motors: 5 x Spike Prime M

Sensors: none

Another clock project, this was inspired by the new Technic plates released in black in the 10323: PAC-MAN Arcade set. I found that if you’re using digits that are 3×4 studs big, the plate is just the right size to fit four such digits with a colon between.

The idea is best understood by watching the video, but in essence it came down to using belts with bricks on them to make “impressions” of digits on freely sliding axles, thus making them show up or disappear from the “faceplate” of the clock. The faceplate consisted of two tilted Technic plates with a gap and then a third Technic plate. Inside the gap, there were four identical digits, each made up of 13 “dots” created using a 180° axle connector with 4L axles coming out of both ends. The connector not only held the axles together but also prevented them from rotating and from sliding out of the tilted faceplate through the pin holes – the angle was such that the axles would slide backwards under their own weight, and the thickness of the rear Technic plate allowed the rear axles to stick out. And since the 4L axle facing the front of the clock was red in every “dot”, pushing the rear axle forward resulted in red “+” appearing in the pin hole inside the front black Technic plate.

Every digit was moved fully back by default, and not visible from the front. Behind the faceplate, there were four belts build using LEGO 5L tracks, controlled by four separate motors and pushed forward or backward by a fifth motor. This mechanism acted like a stamp – the tracks had bricks sticking out of them, forming 5×3 digits, and they would be repeatedly pushed into the faceplate, making the desired “dots” of the each digit appear visible on the clock, then pushed back and the next digit would be rolled into position behind the faceplate. So the clock would go e.g. from 11:58 to 11:59, then 12:00 and so on. There were no seconds indicator, just hours and minutes, so this was supposed to happen once per minute but I sped it up for the video. Also, since the fifth motor pushed all tracks once per “minute”, I added two red axles to the assembly holding the four sliding tracks together, so that they axles would form a colon between hours and minutes every time the digits were pushed.

It was a typical “proof of concept” build and only cared about its working, not its appearance. It was relatively simple, the only real challenge being ensuring that the “stamps” always lined up with the backs of the “dots” correctly. I found that maintaining constant tension of each track was crucial here, which is why my initial prototype had only the front sprockets of each tracks sliding, so that track would get pulled and then loosened, but I ended up sliding the entire track assembly forward and backward, with each motor directly connected to the sprocket and sliding together with it. It was also difficult to make the fifth motor sufficient for pushing forward the entire assembly of four tracks with motors – I had to find the angle which was steep enough for the “dots” to slide back into the faceplate when released, but not so steep that the motor would struggle to push the tracks forwards. Also, using red axles wasn’t the best solution in terms of visibility, but when I experimented with yellow ones, I found them too visible – they would remain partially visible even when retracted into the faceplate.

Photos:

Video:

Kraz-255 27 Jun 2024 6:09 AM (last year)

Model of a Ukrainian heavy-duty military truck. Features 6×6 drive, steering, suspension and a piston engine.

Datasheet:

Completion date: 24/01/2024

Power: electric (BuWizz)

Remote control: BuWizz

Dimensions: length 50 studs / width 17 studs / height 19 studs

Weight: 1.308 kg

Suspension: pendular

Propulsion: 2 x PF L motor geared 3:1

Motors: 2 x PF L, 1 x PF Servo

The Kraz-255 is a known as a “Terminator” among off-road enthusiast because of its legendary cross-country capability. It was designed as an “extreme conditions” military truck, fitted with a powerful V8 engine, ultra-wide tires and it’s so enormous that it’s actually too large to be legally driven on roads. I’ve wanted to build a model of it for a long time, and eventually chose to build one as a proof of concept for a discussion about small-scale off-road LEGO trucks that I was having with the local Truck Trial people. Just to see what is possible, I’ve built a pendular front axle with drive and steering that was just 14 studs wide including wheels. Once this was completed, I had to build a model to test it in.

I’ve chosen to build the cabin is rare LEGO sand green color, following my feeling that such a color looks a little weathered and generally less toy-like than regular LEGO green. The model was initially equipped with LEGO 56 mm tractor tires, but the more I looked at the real truck, the less right they looked to me, until I eventually put 56 mm balloon tires instead. These weren’t perfect either, but I felt they were closer to what the real truck’s wheels look like.

I didn’t feel like building yet another truck with empty cargo bed, so I put over 300 of brown round bricks imitating a pile of lumber on the back. The pile was hollow inside, with opening top and the BuWizz unit hidden inside. The result was that the model’s center of gravity moved significantly backward, which I tried to mitigate by moving the motors and the BuWizz as far forward as I reasonably could. This is why the drive motors show between the cargo bed and the cabin and are visible inside the cabin, which hurts the aesthetics of the model. It also forced me to move the spare wheel higher than it should be, because the motors were right below it. There was plenty of room to put the motor under the “lumber”, but the model would be very rear-heavy if I did that.

The front suspension was a simple pendular axle stabilized with a pair of rubber bands, since there was no room for shock absorbers, and steered by a PF Servo that was blocked to rotate by 45 instead of 90 degrees each side. The two rear axles were also pendular, and connected by a longitudinal pendular unit, making them them able to not only oscillate sideways, but also go up and down. The resulting suspension unit proved too fragile for shock absorbers so I’ve stabilized it with two parallel axles, one above each pair of left/right wheels, which were connected to axles #2 and #3 at the ends, and able to oscillate just like they did. This kept the truck upright without stressing the axles, ensuring that if one wheel went up, the other went down, or in other words that the sum of distances between the wheels and the pivot of the stabilizing axle was always constant. Because the suspension unit holding axles #2 and #3 together was long and connected to the chassis only in the middle, it had a tendency to twist while turning, so I’ve added guides in front and behind it, which essentially acted like forks bracing parts of the suspension unit but still allowing them to go up and down.

I think I’ve spend roughly 1/3 of the total time spent on this model building the hood, so that it looked right, was only 1 stud thick and could be opened without falling apart. It was also challenging to fit a miniaturized V8 piston engine below it. Additionally, the sand green cabin and the “lumber” required a lot of shopping.

The completed model looked OK to me, but turned out to have high center of gravity and moderate sideways stability. On top of that, the front axle had very little ground clearance and few pieces actually protruded in front of the front wheels. This had a seriously negative impact on the model’s off-road performance and I saw no obvious solution to it. Perhaps building a live front axle would be a better option, but this would be difficult to pull off without creating a negative caster angle on it, and the structure required to brace and stabilize such axle would never fit under Kraz’s long, narrow hood. Perhaps it would be a viable option for a cab-over-wheels truck.

Work in progress photos:

Photos:

Video:

AMX-50 Foch 27 Jun 2024 3:10 AM (last year)

Model of a French tank destroyer. Features drive, steering, suspension and remotely controlled traverse & elevation of main gun and the turret gun.

Datasheet:

Completion date: 20/11/2023

Power: electric (Power Functions)

Remote control: SBrick

Dimensions: length 46 studs / width 14 studs / height 11 studs

Weight: 0.736 kg

Suspension: oscillating bogies

Propulsion: 2 x PF M motor geared 2.33:1

Motors: 4 x PF M, 1 x PF Servo, 1 x Micromotor

The AMX-50 project was launched in France promptly after WW2 with the goal of making France competitive tanks manufacturer against US and British vehicles. The program involved four separate tanks, all designated AMX-50, as well as a tank destroyer project intended to provide supporting fire for the tanks. In the end, none of these vehicles made it to production as US Army provided allied countries with free surplus M47 tanks after these were deemed inadequate for the Korean war and started being phased out by the M48 tank. Still, the AMX-50 tank destroyer was an interesting project, largely inspired by the German Jagdpanther, to the point where some design stages involved help from German tank engineers. It was designed with emphasis on firepower and mobility. The destroyer’s distinguishing features included a commander’s cupola with a massive rangefinder and having the main gun mounted in a narrow protrusion on the glacis plate. I thought it would be an interesting challenge to fit a gun with a decent range of motion inside such a protrusion.

The model ended up being near the 1/30 scale and it was a rather extreme exercise in squeezing things inside. In fact, the chassis pretty much ends on top of the tracks and there are only a few bricks above, the rest is all motors and wires. The video below shows the inside view. As a result, the model was quite fragile, but still robust enough to drive along forest paths without falling apart. It housed a total of 6 motors, the 8878 battery and one SBrick. Two PF M motors provided drive and steering while a PF Servo motor was laid flat on the bottom of the chassis and controlled the main gun’s traverse. The PF Servo is a large motor but it didn’t require any gear reduction for that function, so it ended up not needing that much space after all. Another PF M motor controlled the main gun’s elevation while one more PF M and a Micromotor were slaved to the main gun’s traverse & elevation motors and controlled the turret. In order to fit the turret mechanism I had to place the Micromotor right above a track, and it partially showed from under the side armor. The turret was traversed by a PF M motor driving a worm gear meshed with a red t8 gear on an axle – this gear has ability to slide along axles. I’ve used that to control the turret elevation by having the Micromotor push the axle going through the 8t gear up or letting it slide down under its own weight. That didn’t always work as that weight was minuscule and ideally a rubber band should have been used, but I wasn’t able to find enough room for it.

The suspension relied on simple oscillating bogies, but because there was an odd number of road wheels, I had the six rear wheels mounted on three bogies, two wheels each, and the three front wheels mounted on a single bogie with the wheel #2 being its axis and thus effectively not suspended. I have initially used thin beams for the suspension, but they proved so fragile and wobbly that I eventually added extra space between the tracks and the chassis and used regular beams instead.

I was unable to find what color scheme would be historically accurate, as the few remaining photos of the destroyer are exclusively black & white. The World of Tanks game shows all French armored vehicles in a color that can be described as deep sea green, which has no direct LEGO equivalent. I’ve felt that the closest LEGO color is dark turquoise and I’ve started building the body with it, but this is a pretty rare LEGO color and after reviewing the availability and prices of dark turquoise LEGO pieces, I’ve decided to go with simple light gray.

The model definitely didn’t look quite right, especially because the side armor’s angle and length weren’t quite correct. This was in part because the angle of the glacis plate doesn’t match any LEGO wedge pieces, so if I wanted to put the side plates under the glacis plate, this would result in some gaps. Instead, I put the side plates over the glacis plate’s sides. The turret elevation mechanism was notoriously unreliable, and the turret itself was oversized because otherwise I wouldn’t be able to fit the mechanisms in it.

It remains debatable whether there’s really a point in squeezing so many mechanism inside such a small model, because it has definitely impacted its look in a negative way, but it was certainly a good exercise for me.

Photos:

Video:

Motorized Liftgate Truck 9 Oct 2023 11:34 AM (2 years ago)

LEGO Ideas project: a simple truck with motorized liftgate, a working pallet jack and pallets with cargo.

Datasheet:

Completion date: 30/09/2023

Power: electric (Control+)

Remote control: none

Dimensions: length 40 studs / width 15 studs / height 25 studs

Weight: 1.522 kg (including accessories)

Suspension: none

Propulsion: none

Motors: 2 x C+ M

This LEGO Ideas project can be supported here: https://ideas.lego.com/projects/3206ab8f-b660-444b-8052-8563021fb622

A simple truck that I developed in an attempt to bring some Technic into LEGO Ideas. It was inspired by various delivery trucks I keep seeing around the town, which often sport custom-built cargo boxes with somewhat cartoonish proportions. My focus was on playability, so the truck is manually driven and steered but the two liftgate functions: tilt and elevation, are motorized using “dumb” Control+ hub with two levers. This means that the truck requires no app and no smartphone, because the motorized functions are lever-operated. I’ve had opportunity to operate a liftgate on a real truck and found it quite interesting, but at the same time I haven’t seen a single Technic set featuring such a function.

The truck sported steering controlled by a knob on the cabin’s roof, coupled with a working steering wheel inside the cabin. The cabin doors could be opened and the liftgate could be tilted and lifted with motors. For extra playability, I have added a simple pallet jack with working steering and lifting mechanisms, along with three pallets, two of them with appliances on them. Additionally, a section of the cargo box’s roof could be removed to access the batteries in the Technic hub.

The entire project was a balancing act. I was trying to approach it like a LEGO set on a budget, so it was size VS functionality, looks VS playability and so on. The looks were quire obviously secondary to functions. Basically, my goal was to build a Technic set of a kind I’d like to play with, and I don’t like having to use a smartphone as well as having to rotate linear actuators manually, which takes ages. I’ve tried to keep it in the “pure Technic” spirit.

The primary challenge was fitting the dumb hub with two motors and two complex linkages beneath the cargo box. The result is that the cargo box is sitting quite far off the ground, but I thought that this may actually be an advantage, because what’s the point of building a complex liftgate if you only lift things a little? Another challenge is that I was trying to make the motorized functions safe to play, meaning that the ends of the liftgate’s range of motion would converge with ends of the linear actuators’ range of motion. It was demanding to design, but the result was that e.g. when the lift reached topmost position, you could keep the motor running and it would simply make the clutches in the linear actuators slip instead of trying to jam the liftgate into the cargo box. Finally, I was trying to keep the liftgate itself as flat as possible. I have managed all that, but at the cost of some imperfect geometry – namely, when the liftgate reaches its topmost position, it’s still a bit lower than the floor of the cargo box.

The truck was a nice challenge and presented me with some unusual factors to balance against each other, and it ended up being very playable.

Photos:

Video:

Gama Goat 9 Oct 2023 11:05 AM (2 years ago)

Model of an offroad vehicle developed for US Army. Features 6×6 drive, steering, articulated chassis and suspension.

Datasheet:

Completion date: 26/09/2023

Power: electric (Control+)

Remote control: Control+

Dimensions: length 46 studs / width 19 studs / height 18 studs

Weight: 1.644 kg

Suspension: double wishbone

Propulsion: 2 x C+ XL motor geared 2.33:1

Motors: 2 x C+ XL, 1 x Spike L

Gama Goat, or M561 Gama Goat as it was officially called, was US Army’s response to the difficulties in traversing Vietnamese jungle. Where standard trucks struggled, this articulated and amphibious vehicle worked just fine and became renowned for its extreme cross-country capabilities. Over 14,000 units were built and remained in use until 70’s, when high maintenance costs made the US Army replace them with more conventional vehicles, including Humvee.

The vehicle was quite unusual as its chassis was split into two pieces. The front part sported 4 wheels, place for a driver and one passenger, and engine bay. The rear part included just 2 wheels and was entirely occupied by a cargo box accessed via a rear ramp. The joint connecting the two parts worked like a live axle joint, that it is allowed up/down movement and rotating along the longitudinal axle, but not turning to sides. The vehicle was steered by turning the wheels on first and last axle. The body was made entirely of aluminum, making it one of the few military vehicles that could be punctured with a knife or even a sharpened stick. Interestingly, the vehicle was just as unreliable as it was unstoppable – the official requirement of driving 32,000 KM in the field tests without breaking down has never been fulfilled by it.

My model was inspired by the need to test several new LEGO pieces, including the Control+ XL motors, the 5 studs long CV joint and the heavy-duty sliding CJ joint. In order to keep the model 17 studs wide, as dictated by the scale, I’ve used live axles in front and rear, and trailing arms suspension in the middle axle. This was V1 chassis and it performed well until I added more weight to it, at which point the torque effect started to heavily tilt the body sideways when starting and stopping, impairing the steering system in the process. I was unhappy with it, so I’ve kept the body but rebuilt the entire chassis from a scratch using double wishbone suspension, which negates the torque effect. The result was that the total width of the axles went from 17 to 19 studs, so in order to at least partially hide this I made the body 18 studs instead of 17 studs wide.

The chassis was driven by two hard-coupled Control+ XL motors. I had a hard time finding room for them until I eventually used them as stringers between front and rear axle – their shape made them work perfectly for it. Due to limited space, the steering was controlled directly by a Spike L motor with a driveshaft going through it. I couldn’t get the LEGO Powered Up app to handle such direct steering correctly, so I eventually resorted to using the third-party Brickcontroller 2 app, and it worked flawlessly. The first and last axles sported open differentials, whereas the middle axle used a 28t gear instead.

For the body, the reasonable choice would be to build it using studless pieces to keep it robust, but I liked the little details too much and went with System pieces instead. In addition, I’ve spent too much time looking at plastic Gama Goat kits in US Army olive drab no. 3 color, and I came to the conclusion that my model needs body in dark tan. This was a color I’ve never used before so extensive shopping followed, at a massive expense to my LEGO budget, but I kept thinking of it as of investment because I’d like to re-use this color in the future.

In any case, the model ended up combining quite solid, well-performing chassis with an extremely fragile body, so driving it was fun as long as you didn’t mind body parts falling off while negotiating obstacles. In the end, the model provided me with a lot of satisfaction, crippled finances and a promising new color for my future military projects.

Photos:

Video:

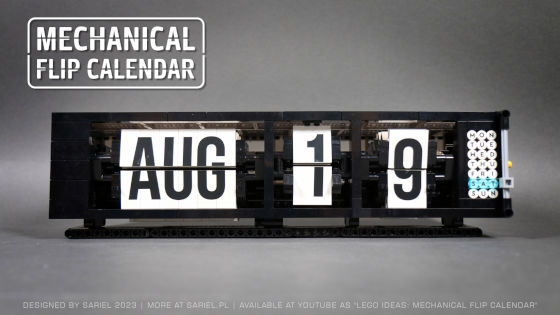

Mechanical Flip Calendar 18 Aug 2023 1:35 PM (2 years ago)

My second LEGO Ideas project featuring a flip mechanism.

Datasheet:

Completion date: 18/08/2023

Power: none

Remote control: none

Dimensions: length 47s / width 16s / height 13s

Last year I have submitted a Mechanical Flip Clock project to LEGO Ideas where it became unexpectedly popular, reaching 10,000 votes within a month of submission. This came as a complete surprise to me, but the LEGO group has ultimately rejected the project. It occurred to me that since the idea was so popular, perhaps it deserves a second try but with a project that would be free from issues that I could identify as making the LEGO group less likely to accept it as an official set.

I’ve come to think that the clock project was:

- bad-looking and half-finished in appearance

- too complex, requiring a motor and prone to inaccuracy

- required too many unorthodox building techniques e.g. to build a dodecagon

- required placing stickers over multiple pieces, which is something the LEGO company is trying very hard to avoid

With these points in mind, it occurred to me that a device that can use a flip mechanism without requiring a motor and worrying about accuracy is a calendar, since it’s usually operated manually and its accuracy depends solely on the user. An actual starting point for the project was coming across the recently introduced 4×4 LEGO tiles, which solved the issue of stickers placed over multiple pieces: I could use just one such tile for upper flap and another for lower flap. This solved the stickers problem for digits, and as for the months, which needed flaps three times as long, I have used three 4×4 tiles and shortened all month names to three letters, so that margins between stickers/prints could simply fit between the letters.

On the mechanical side, I have abandoned circular structures in favor of a sort of a conveyor belt built using 3L Technic beams and wrapped in a closed loop around a liftarm of specific length. This formed a flattened loop which could be easily moved by rotating a 3L beam on an axle so that it meshed with gaps between 3L beams on the conveyor belt. Moreover, by rotating that axle by exactly 90 degrees at a time, it was possible to move the conveyor belt by a single flap at a time. The resulting “counter” was also relatively small and much lower than circular structures in my clock project.

The central counter, showing tens of days, was an exception because it didn’t require a conveyor belt. With only 4 flaps required for this counter, I was able to simply build a connector rotating on an axle and holding all 4 flaps.

I went through several iterations of flaps before arriving at two tiles joined back to back using a modified plate piece. Additionally, each flap had two spacers on its back side that would lean against the next flap, thus keeping the flap nearly vertical when in upper position. Without the spacers, the upper flaps had a tendency to lean back against the next upper flap.

To keep the calendar simple, small and clean, I didn’t synchronize the three counters in any way, instead making each operated by turning a knob sitting on an axle going through a modified brick that was squeezed from two sides by Technic connectors connected with a rubber band. Thus simple stepper mechanisms were created, breaking the rotation of the knobs into steps of 90° each, which in turn translated into moving each respective counter by one flap – and that was possible both forward and backward. Any kind of mechanical synchronization would dramatically increase the complexity level (considering synchronizing months of various lengths mechanically) while also keeping the counters further apart. For the same reason I kept simple knobs for operating the counters, because I’ve tried adding several various lever/button mechanisms instead, and each of these would require plenty of space, introduce significant structural stress due to rubber bands, and then it would end up jamming frequently. In the end I’ve decided that knobs are more reliable thanks to their simplicity.

Finally, I put the whole mechanism inside a simple, clean housing with large trans-black sections that allowed to see the inside, and I’ve added a simple manual indicator for day of the week on the housing’s front.

This project can be supported here: https://ideas.lego.com/projects/5f7b16ea-2abb-4278-aed2-0c8036280139

.jpg/128x72.jpg)