Dropshipping: Your online shop. Our premium made-in-the-USA t-shirts. 15 Oct 7:10 AM (6 days ago)

Fulfillment Orders: Direct to Your Customer

Let us handle production and shipping so you can focus on growing your brand. With on-demand printing, your customers get the highest-quality, sustainably made t-shirts directly from your online store to their door.

- Your customers order from your website

- We integrate your site (Shopify and other platforms, some exclusions) with our shipping system

- Orders are printed on demand and shipped directly to your customers

Explore Dropshipping Options

Building Better Apparel, Together

By partnering with TS Designs, you’re supporting a transparent and sustainable supply chain and helping bring apparel manufacturing back home. Join us in building a better way forward.

Shop sustainably made printed t-shirts for your company, organization, or events

Don’t need printing? Add a meticulously crafted, locally grown and made t-shirt to your wardrobe

Always made in the USA, TS Designs produces premium printed apparel through a transparent, domestic supply chain. On our journey toward circularity, we champion natural fibers and dyes to help reduce microplastics in the environment.

The post Dropshipping: Your online shop. Our premium made-in-the-USA t-shirts. appeared first on TS Designs.

Garment Dye: Why it Makes a Better T-Shirt 22 Sep 7:22 AM (29 days ago)

Garment dyeing is a technique that creates a super-soft and vintage feel that is already broken-in. It’s the process of dyeing white garments (or in our case, t-shirts) AFTER they have been sewn and constructed. A majority of clothes get their color from dyed rolls of fabric.

Our 5,000-square-foot dye house, near downtown Burlington, NC, has 5-sample and 9-production paddle dye tubs. These paddle dye machines, built in the 1960s, were used by Kayser-Roth to dye socks made in the same building.

This system is great for inventory control because we only have to stock white t-shirts. Garment dyeing gives us the flexibility to respond to real demand by allowing our customers to choose color at the last stage of the ordering process.

Teaser: Dye House of the Future

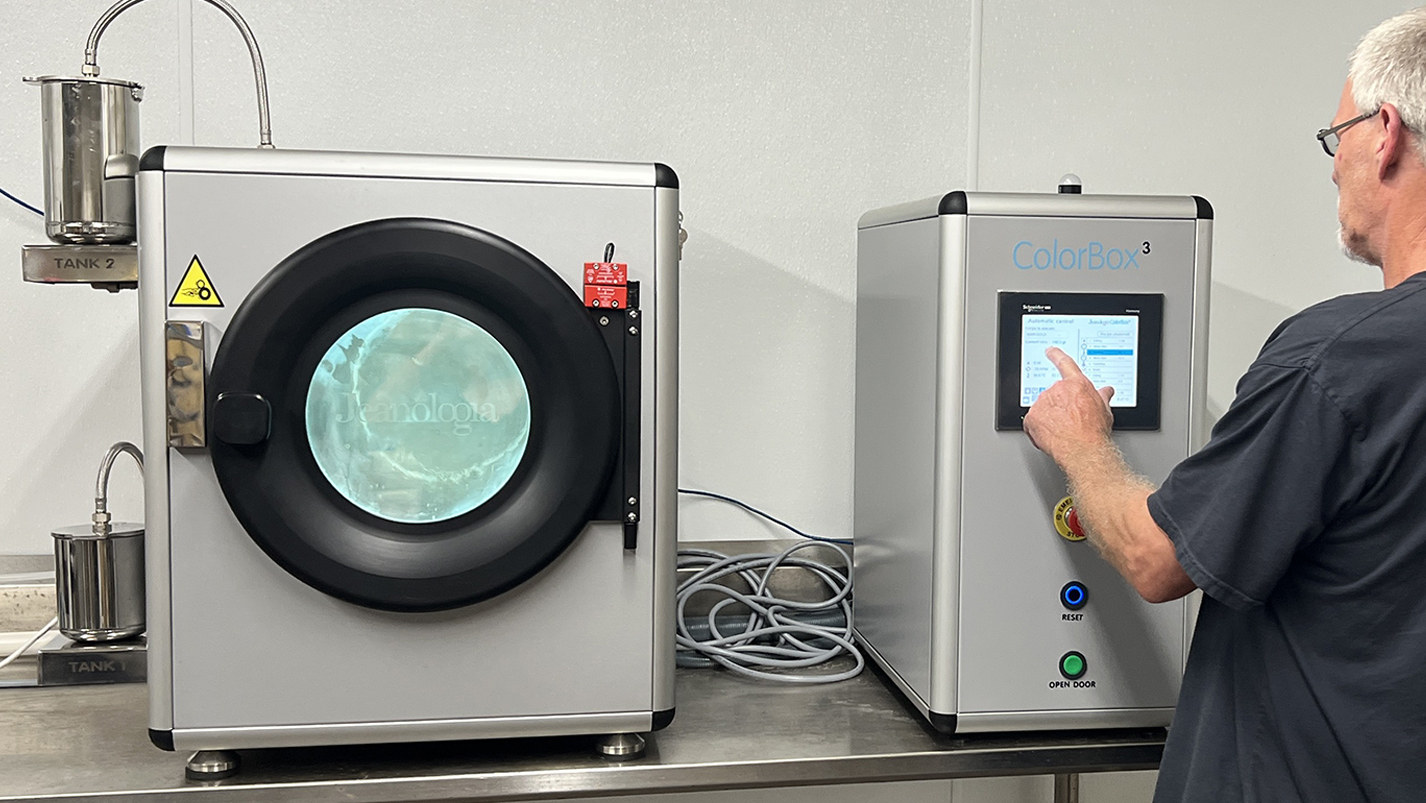

A few years ago, we identified the ColorBox. This garment dyeing equipment by Jeanologia is the most advanced garment dyeing technology available today.

Although our current dye house has served us well, this new, more modern version of dyeing apparel is less labor-intensive and conserves valuable resources like water, energy and CO2.

We recently received our first sample version of the ColorBox to begin validating its effectiveness. This marks the first step toward building a larger, more advanced dye house, positioning us to compete in an industry still ruled by overseas manufacturing.

Beyond efficiency, this machine gives us greater control over dye results and supports our mission to make natural dyes a viable alternative in a marketplace dominated by overseas, synthetic, fossil-fuel-based dyes.

For instance, we are currently testing a batch of natural dye made from Marigolds grown in our on-site dye garden!

We believe garment dyeing is a powerful path forward for manufacturing in the USA. Not only does it produce beautiful depth of colors on apparel, but it also gives customers greater flexibility by allowing color to be chosen later in the process. With this approach, we are proving that clothing made domestically with natural fibers can successfully compete in the global apparel industry.

Shop sustainably made printed t-shirts for your company, organization, or events

Don’t need printing? Add a meticulously crafted, locally grown and made t-shirt to your wardrobe

TS Designs is a t-shirt manufacturer that produces the highest quality printed apparel through a domestic, transparent, and trackable supply chain. We use only natural fibers & earth friendly printing, always grown and made in the USA.

The post Garment Dye: Why it Makes a Better T-Shirt appeared first on TS Designs.

Where Your Clothing Relaunch 28 May 8:58 AM (4 months ago)

Building a more resilient and equitable apparel industry

Why Transparency Matters

Today, overseas manufacturing operations make up 98% of the clothing we purchase here in the United States. This makes it difficult to learn anything about where our clothes come from, or to exercise our buying power to influence the market.

We believe consumers have a right to know the supply chain for all apparel, and they do for TS Designs t-shirts, from the farmers who grow the cotton to the folks who sew the cloth together. That’s why back in 2008, we launched Where Your Clothing with our flagship Cotton of the Carolinas t-shirt, allowing customers to trace every step of their shirt’s journey.

It’s not just about curiosity, it’s about accountability. We believe that knowing where your clothing comes from is the first step toward building a fairer, more sustainable apparel industry.

Today, We are excited to relaunch WhereYourClothing.com, an upgraded, interactive tool that lets you trace every step of your TS Designs t-shirt’s journey.

Try it out! Break out your old TS Designs or Solid State Clothing t-shirt and head on over to WhereYourClothing.com. If you don’t have one, take a look around the site and learn about us:

-

QR Code: If there is one on your shirt just scan it to take you directly to its page

-

Track Your Apparel: If there is a 12 digit code on your shirt’s neck label enter it on the home page

-

Supply Chains: Search by brand if there is not a code

-

Partners: You can see our partners who have branded supply chain pages. Ask us if you would like to inquire about having yours!

The website shows you where your garments were grown and made, reinforcing our commitment to radical transparency throughout the entire production process. We supply an image of the contact person, their phone number, email, and a physical address for the manufacturers in our supply chains.

This level of access may seem simple, but it’s incredibly rare. Most clothing brands don’t share any part of their supply chains and many don’t even know them, nor have any interest in finding out.

Note: We provide as much information as possible, however we lack access to some of the information in the supply chains that we do not directly control. As it is not normalized for companies to ask details, the information is often lost or never tracked to begin with. Our long-term goal is to create an apparel system that normalizes transparency, but for now, we will continue to ask the questions that so many have ignored.

We think it’s time to change and it starts with you. When you know where and how your clothes are made, you can make more informed choices. By exercising your buying power, you can help shift the apparel industry toward greater transparency, fairness, and sustainability.

Shop sustainably made t-shirts for your company, organization, or events

Don’t need printing? Add a meticulously crafted, locally grown and made t-shirt to your wardrobe

TS Designs is a t-shirt manufacturer that produces the highest quality printed apparel through a domestic, transparent, and trackable supply chain. We use only natural fibers & earth friendly printing, always grown and made in the USA.

The post Where Your Clothing Relaunch appeared first on TS Designs.

Wood Chips for Community 17 Apr 5:20 AM (6 months ago)

TS Designs sits on four and a half acres and early on we adopted a permaculture plan. We strive to maintain a diverse native landscaping environment that goes beyond simple aesthetics.

Just in time for Spring we were ready for wood chips. We use them for composting and landscaping. In the past we would get from Chip Drop that supplies free wood chips to gardeners. Lately they have been hard to track down in our area.

As fate would have it our president Eric Henry heard a truck that sounded like chipping wood near our facility. He dashed over and what do you know it was wood chips! When he asked if we could have them they said “Sure!” and drove right over and dropped them off in our parking lot. In exchange Eric invited the workers to our Breakroom Boutique to pick out a few t-shirts for their efforts. Thanks guys!

Local Connected Models

TS Designs is closely knit with the community. Wood chips are a common thread with initiatives we are involved in that work to unite community.

Commercial Composting Initiative

A promising initiative Eric is working on is the development of a commercial composting system in our area. Discussions are underway and bringing this to life will require commitment from local government, farmers, and the broader community. Wood chips will provide the carbon media for this initiative, which will affect community in the following ways:

-

Redirecting food waste from landfills

-

Allowing backyard chickens within city limits to reduce food waste and enhance the local food supply—we all know about egg prices…

-

Repurposing food waste such as coffee grounds, avocado pits, and onion skins for natural garment dyeing that could replace globally produced, fossil fuel derived synthetic dyes

-

Combining food and yard waste to create compost, reducing dependence on fossil fuel-derived fertilizers

Piedmont Agrarian Collaborative

The recent initiative Eric created with our friend and collaborator Josh Humphreys, Piedmont Agrarian Collaborative (PAC), is another case in point. It provides food from the farmer to the eater by bringing together a diverse group of small farms (including Henry Family Farm) committed to regenerative farming practices. One pick-up point is located at the TS Designs facility! When we have them, we share our wood chips with the PAC farmers.

“In these chaotic times collaboration is key to support each other and move forward. Collaboration gives us a broader perspective of people’s views, opinions, and ideas, which in turn builds more connected, resilient communities.” — Eric Henry, President TS Designs

The post Wood Chips for Community appeared first on TS Designs.

Slow Fashion: Why Our Printed T-Shirts Cost More 27 Mar 7:47 AM (6 months ago)

When ordering t-shirts for your company, event, or organization, cost is often the first consideration. But have you ever stopped to think about where those shirts come from and how they’re made? Many fashion brands prioritize the lowest price, pressuring overseas factories to cut costs—often at the expense of apparel workers and the environment.

At TS Designs, we do things differently. Our triple bottom line business model means every decision we make considers what’s best for people and the planet. That’s why our shirts may cost more—but they’re made to last, support ethical manufacturing, and contribute to a more sustainable future.

“In these chaotic times collaboration is key to support each other and move forward. Collaboration gives us a broader perspective of people’s views, opinions, and ideas, which in turn builds more connected, resilient communities.” — Eric Henry, President TS Designs

What Goes into Our Slow Fashion T-Shirts?

-

Transparent Supply Chain: Only 2% of garment workers worldwide earn a living wage. We source every step domestically, ensuring fair pay and full supply chain transparency.

-

Fabric: Cotton costs 25% more than fossil-fuel-based fabrics, but we’re committed to 100% natural fibers—even down to the thread. Our Cotton of the Carolinas shirts use cotton locally sourced from a farmer who we negotiate fair pricing with.

-

Quality: Made with 100% US-grown ring-spun cotton, our shirts are ultra-soft, durable, and pill-resistant for years of wear. This compares with some brands that offer only open end or air jet yarns, resulting in a rougher hand and less durable fabric. Since organic cotton is not readily available in the US, we use some GOTS certified cotton threads from overseas. Stay tuned as that may change soon!

-

Eco-Friendly Printing: Unlike traditional screen printing, our REHANCE™ process embeds the design into the fabric for a soft, long-lasting print—without fossil-fuel-based inks. This process took us years to develop and is only available at TS Designs.

-

Garment Dye: Each shirt is garment dyed, therefore it is preshrunk and broken in for a vintage, ultra-soft feel from day one.

That is why when we say TS Designs has set out to make the highest quality and most sustainable printed t-shirts on the planet, we back it up with a commitment to doing things the right way—not the cheapest way.

We believe every t-shirt should reflect your values of sustainability, quality, and ethical production, and we can’t do it without you. If your business or organization is ready to make a difference with better t-shirts, click below to get started.

The post Slow Fashion: Why Our Printed T-Shirts Cost More appeared first on TS Designs.

Looking Back on 2024: TS Designs’ Commitment to a Better Apparel Industry 23 Feb 6:27 AM (8 months ago)

The TS Designs team was hard at work last year—not only making the best darn t-shirt with a fully trackable, made-in-the-USA supply chain but also shaking up the apparel industry by engaging with our community, launching a nonprofit, and gaining recognition through multiple media features.

Initiatives Launched

Know Your Clothing

Last year we launched Know Your Clothing, a nonprofit initiative who’s mission is to “Cultivate resilient apparel communities through circularity, transparency, and equity.” This new vision for the apparel industry provides consumers with choices to make conscious decisions of what to buy based on their values, while simultaneously eliminating waste and reducing negative environmental impacts. We are excited about this collaboration with Croatan Institute, who has fiscally sponsors the project.

Piedmont Agrarian Collaborative

Piedmont Agrarian Collaborative (PAC) was launched in 2024 by Eric Henry, and Joshua Humphreys of Pont Reading Farm to provide food right from the farmer to the eater. One pick-up point is right here at the TS Designs facility.

The Piedmont Agrarian Collaborative brings together a diverse group of small farms committed to regenerative farming practices that enhance soil health and sequester carbon. We strive to provide our North Carolina communities with fresh, locally-grown fruits, vegetables, meats, eggs, and more, fostering sustainability and connection to the land. Learn more at Pac.Farm.

Solid State Clothing

Solid State Clothing is our retail brand, and it’s our way to bring our meticulously crafted, locally grown and made shirts directly to your wardrobe. Solid State releases small batches of premium-quality t-shirts that are durable and versatile for work, play, and everything in between. It’s also our platform for experimenting with new materials like natural dyes and creative collaborations with regional artists and makers.

2024 Solid State Clothing Product Launches

Georgia Pocket T-Shirt

A classic crew-neck pocket t-shirt, made from 100% cotton directly sourced from Warbington Farms in Cummings, Georgia. We made this shirt in partnership with Magnolia Loom, an apparel company as dedicated to domestic manufacturing and farming as we are.

Ball Cap I

Solid State Clothing brings you our first ball cap. Made by Unionwear in New Jersey, USA. With a clear vision, we’ve mapped out a multi-phase plan to evolve our hats to be completely circular over time.

NC Cotton + Tara Reed Graphic T-Shirt - Fall Skull Garden

Limited Edition and no longer available! This Fall Skull Garden was created to showcase a local Raleigh, NC artist, Tara Reed’s work on a locally made t-shirt.

Naturally Dyed Hemp Beanies

Our pioneering Hemp Beanie is one of the first pieces of clothing made from U.S.-grown hemp. It’s a year-round knit hat made from a 30% American hemp, 70% American cotton blend that’s comfortable, breathable, durable, and 100% natural. Naturally dyed with avocado pits, Osage orange, black walnut or natural.

Natural Dyed Wool Beanies

Our 100% Wool Beanie is a testament to natural craftsmanship and sustainability. Made entirely from premium, U.S.-sourced wool, this year-round knit hat offers warmth, breathability, and unmatched comfort. Naturally dyed with black beans, black walnuts or natural.

Our fashionista runway models included employees, Jessika and Emily in addition to a group of talented young folks who brandished our sustainably made clothing.

Behind the scenes, Ilsa, Jesika, Eric, Ken, Kaitlin, Emily & Joe staffed our booth, showed support and made things happen.

ROAR Women's Symposium

In the springtime we were a vendor at this dynamic event hosted by the Alamance Chamber of Commerce to empower women through keynotes, panel discussions, and networking opportunities. This event celebrates women’s strength, resilience, and impact in the community.

Saxapahaw Holiday Market

Held annually at the Haw River Ballroom, we find our kinsfolk shopping Solid State Clothing alongside many other artisan vendors just in time for the holidays!

TS Designs in the Media

Climate Town: Fast Fashion is Ruining Merch

Climate Town is Rollie Williams and a ragtag team of climate communicators, creatives and comedians who examine climate change in a hilarious yet educational way. In this episode TS Designs is featured as a sustainable alternative for t-shirt merch! A must watch if you haven’t seen this yet.

All the Media

Our CEO Eric Henry continues to be asked to speak or contribute to multiple publications and podcasts over the year around our mission to sustainability.

Podcasts

- Story of a Startup: Creating Sustainable Brands with Eric Henry (CEO, TS Designs)

- ASI Media Promo Insiders: Why Natural Fibers & Dyes are Key for Apparel Sustainability

- How I Built My Small Business: Crafting an Eco-Friendly Clothing Empire with TS Designs and the Fight Against Fashion’s Waste Crisis

- Big News Network: U.S. businesses adopting Environmental, Social and Governance practices

- The Hometown Holler: People, Planet, Profit

Television

- Fox 8 News: TS Designs wants you to ask questions about your shirts

Publications / Blog Articles

- eTextileCommunications: Eric Henry driving TS Designs to reclaim America’s apparel heritage – naturally, sustainably

- Ignation Solidarity Network: Fordham Becomes CEPA Partner

- Big News Network: U.S. businesses adopting Environmental, Social and Governance practices

- Black Walnut Project White Paper: A team of Sustainable Innovation MBA students from the University of Vermont, led independent research and interviews with potential collaborators to aid in developing a system to commercially leverage black walnuts as a natural dye material.

Customer Spotlight

We love our customers and their commitments to sustainability. In an effort to dive deeper, we developed our Customer Spotlight series, where we feature interviews with them on the TS Designs Blog.

- Yonderlust: Kit and Sonya Linton

- Two Tired Parents: Jessie and Ryan Stasiak

- Rolling Hills Gin: Wes Morgan (Supplier Spotlight)

- Carrboro Farmers Market: Maggie Funkenhouser and Laura Perez

- Gilson Snow: Nicholas Gilson and Austin Royer

- Hillsborough United Church of Christ: Jay Kennett

- Climate Town: Rolllie Williams and Matt Nelsen

- Burlington Beer Works: Tracy Schmidt

- Mutts Comic: Ali Datko and Patrick McDonnell

- Sustainable Angler: Rick Crawford

- Chapman Trading Co. and Magnolia Loom: Zeke Chapman

Looking Toward the Future

As we look toward 2025, our commitment to sustainability remains unwavering. We will persist in promoting DEI, climate change awareness, in addition to our domestic manufacturing, transparency, and sustainable practices. No matter the political climate, our resolve remains strong as we continue to bring full transparency to the global apparel supply chain.

Shop sustainably made t-shirts for your company, organization, or events

Don’t need printing? Add a meticulously crafted, locally grown and made t-shirt to your wardrobe

TS Designs manufactures the highest quality printed t-shirts in a domestic, transparent, and trackable supply chain. We work with brands who want to provide their customers with responsibly made clothing that positively impacts people and the planet.

The post Looking Back on 2024: TS Designs’ Commitment to a Better Apparel Industry appeared first on TS Designs.

Good News Bad News: Textile Waste Recognized as a Concern by U.S. Government 14 Jan 9:55 AM (9 months ago)

Waste from Apparel Industry Recognized as a Concern by the U.S. Federal Government

Breaking News as the Congressional Slow Fashion Caucus Takes Action

TS Designs President Eric Henry eagerly joined in support when Congresswoman Chellie Pingree (D-Maine) announced the first-ever Congressional Slow Fashion Caucus in June 2024. According to Rep. Pingree’s site the principles of the Slow Fashion Caucus include:

- Incentivize apparel industry to promote reuse, repair, and recycling of textiles

- Develop “circular economy” policies to drive the apparel industry to reduce natural resource consumption

- Promote textile reuse and recycling infrastructure

- Bring textile production back to the USA

- Support the use of more sustainable fibers

- Expand initiatives across federal agencies to encourage textile sustainability

The Caucus asked the U.S. Government Accountability Office (GAO) to review their concerns and on Dec 12, 2024 the GAO released this groundbreaking report, Textile Waste: Federal Entities Should Collaborate on Reduction and Recycling Efforts (summary report), recognizing the growing problem of textile waste, and the need for an interagency mechanism to connect federal agencies in addressing this challenge, minimizing redundancy in research and development efforts.

The GAO’s full report recommends that Congress consider directing a federal entity or entities to coordinate efforts and take action to reduce textile waste and advance textile recycling. The report also describes:

- how textile waste affects the environment;

- how and why the rate of textile waste in the U.S. has changed in the last 2 decades; and,

- federal actions to reduce textile waste and advance textile recycling, and what opportunities exist for entities to collaborate.

Although post-consumer textile recycling is important, an astounding 30% of clothing manufactured never even reaches the consumer, instead ending up being burned or dumped in landfills.

Biden Administration’s Response

The Office of Science and Technology Policy (OSTP) was quick to respond, denying the need for a federal interagency task force. They agreed on many of the findings of the GAO report but at this time the federal mechanism for managing it does not and will not exist.

You can read an in-depth look into what this means to the textile industry, in this Sustainable Fashion Forum‘s article, What the Biden Administration’s Response to GAO Means for Textile Waste in the US.

The Slow Fashion Solution

Slow fashion prioritizes quality over quantity, encouraging ethically made, long-lasting clothes.

By recognizing the consequences of fast fashion and supporting sustainable practices, we can make more informed choices about the clothes we buy and the waste they generate.

It’s time to move beyond the fast fashion mindset and invest in brands that actively prioritize what’s best for both people and the planet.

Shop Slow Fashion: Supporting TS Designs, Solid State Clothing, and nonprofit initiative Know Your Clothing

Despite the competition from low-cost fast fashion, TS Designs will stay the course and continue on the path of sustainability, including creating for and contributing to the Slow Fashion model.

Please continue your support by ordering long-lasting, high-quality apparel in these times when the cheapest is not the best way to go.

- Need shirts printed for your organization or an event? TS Designs has sustainable and circular options. Visit TSDesigns.com, pick one of our brands, and request pricing.

- Don’t need printing? Add a meticulously crafted, locally grown and made t-shirt or other sustainable apparel to your wardrobe with our retail brand Solid State Clothing.

- Support R&D around creating more sustainable fashion solutions by donating to our nonprofit initiative, Know Your Clothing, a fiscally sponsored project of Croatan Institute, a registered 501(c)(3) public entity.

Shop Sustainably Made T-Shirts for Your Company, Organization, or Events

Don't Need Printing?

Add a meticulously crafted, locally grown and made t-shirt to your wardrobe.

TS Designs manufactures the highest quality printed t-shirts in a domestic, transparent, and trackable supply chain. We work with brands who want to provide their customers with responsibly made clothing that positively impacts people and the planet.

The post Good News Bad News: Textile Waste Recognized as a Concern by U.S. Government appeared first on TS Designs.

The Hidden Cost of Packaging Waste in the Apparel Industry 20 Nov 2024 4:42 AM (11 months ago)

How many times have you received a package, only to discard the packaging without a second thought? Most people would likely answer, “nearly every time.” This casual habit has a significant environmental impact, especially in the apparel industry, which generates millions of tons of plastic waste annually.

The Impact of E-Commerce on Packaging Waste

The rise of e-commerce has dramatically changed the way we shop. With the increase of online shopping comes the demand for packaging materials to protect goods. According to a recent OECD report, nearly two-thirds of plastic waste have lifetimes of under five years, with packaging accounting for 40%. Consumer goods take up 12%, with clothing and textiles at 11%.

Not only is the packaging itself harmful, it also leads to an increase in waste that is either difficult or impossible to recycle. Alarmingly, only 9% of plastic waste is recycled, while the rest accumulates in landfills, uncontrolled dumpsites, or is incinerated. This emphasizes the urgent need for systemic change in how we handle packaging and waste in the apparel industry.

A Study on the Apparel Industry’s Plastic Footprint

A 2019 study, “The Global Apparel Industry is a Significant Yet Overlooked Source of Plastic Leakage,” highlights the troubling role the apparel industry plays in the global plastic pollution crisis. The study examines the role of different fibers—synthetic, cotton, and other materials like hemp, wool, and acetate—which together account for 52%, 23%, and 25% of global fiber production, respectively.

The study found that synthetic apparel is the largest contributor to plastic waste in the apparel industry, accounting for 81% of the plastic waste produced. Cotton apparel generates plastic waste primarily from packaging, with a small portion coming from the use of plastic mulching in cotton fields. In contrast, packaging is the main source of plastic waste in other fiber value chains. Overall, synthetic apparel is responsible for 89% of macroplastic waste from the apparel industry, while cotton and other fiber value chains contribute just 9.4% and 1.5%, respectively.

How You Can Help Reduce Packaging Waste

You may be wondering: What can I do to lessen the impact of apparel packaging waste? The solution starts with us—consumers.

Here are a few simple steps you can take to help:

- Shop with Reusable Bags: Use natural fiber or recycled tote bags, such as Beer to Bags. They are both stylish and functional! Bring your own reusable bags when shopping, especially to small businesses in your area.

- Choose Eco-Friendly Retailers: Many online retailers, such as Solid State Clothing, are dedicated to sustainability and offer packaging made from recycled or biodegradable materials.

- Repurpose Packaging: When you receive a package, consider reusing the packaging for future shipments or for storage purposes. This helps reduce waste and saves you money.

- Recycle What You Can: If the packaging is recyclable, make sure to recycle it properly. However, if it is not recyclable, ensure that it is disposed of responsibly—littering is both harmful and illegal.

- Choose Eco-Friendly Packaging: If you yourself, are looking for ways to package, consider using a brand like EcoEnclose.

Shop Sustainably Made T-Shirts for Your Company, Organization, or Events

Don't Need Printing?

Add a meticulously crafted, locally grown and made t-shirt to your wardrobe.

TS Designs manufactures the highest quality printed t-shirts in a domestic, transparent, and trackable supply chain. We work with brands who want to provide their customers with responsibly made clothing that positively impacts people and the planet.

The post The Hidden Cost of Packaging Waste in the Apparel Industry appeared first on TS Designs.

Customer Spotlight: Chapman Trading Co. and Magnolia Loom 12 Nov 2024 8:48 AM (11 months ago)

Chapman Trading Co.

We are thrilled to feature Chapman Trading Co. and Magnolia Loom as our November Customer Spotlight! Founded by Zeke Chapman in 2015, Chapman Trading Co. has come a long way since its formation. After graduating from high school, Zeke taught himself how to screen print in the back of his dad’s office. Today, the company offers a wide range of services, including custom screen printing, embroidery, signs and banners, promotional products, and paper items. Chapman Trading Co. is the parent company of Magnolia Loom, a brand established in 2021 to meet the demand for a Georgia-grown and sewn t-shirts. What began as a new initiative has now grown into a line of 100% cotton garments that are completely made in the USA—from seed to shirt.

Giving Back to the Community

When Hurricane Helene devastated Georgia, Zeke and his team knew they had the resources and the determination to help their community rebuild. With the support of their customers and their own contributions, Chapman Trading Co. raised nearly $45,000 to aid farmers and FFA chapters in the affected areas. This effort reinforces their commitment to making a positive impact beyond business. In addition, Magnolia Loom gives back by donating a portion of the proceeds from every shirt to the Georgia Foundation for Agriculture. This organization is vital in securing the future of U.S. agriculture by supporting farmers and their communities. So far, Magnolia Loom has helped raise over $30,000 for the foundation.

Sustainability Commitment

Sustainability is a fundamental principle in Chapman Trading Co.’s operations. They prioritize making their garments traceable, reducing their environmental footprint, and ensuring that their products tell a meaningful story that resonates with others. Zeke firmly believes in doing things the “hard way” because it’s the right way. Raised with a deep respect for the land, he is dedicated to leaving it better than he found it. One of the most creative ways Chapman Trading Co. embraces this philosophy is through their sustainable t-shirt production.

Partnering with TS Designs

In 2022, Zeke developed an interest in garment dyeing and began researching U.S.-based garment dyeing facilities. This led him to TS Designs, where we have one of the last remaining domestic dye houses. Garment dyeing offers greater flexibility in production while improving the quality of the final product. After building a strong working relationship with TS Designs, Chapman Trading Co. began dyeing for their Magnolia Loom line, achieving exceptional results.

Exciting Developments

Chapman Trading Co. is currently merging with their cut-and-sew partner to create a more efficient, closer supply chain. The new business, called Rally Apparel Co-Op, will be a joint venture between FAM USA and Chapman Trading Co. This move opens up exciting opportunities for product development, improved efficiency, and cost savings. With this new establishment, Chapman Trading Co. has a lot to look forward to in the future!

TS Designs manufactures the highest quality printed t-shirts in a domestic, transparent, and trackable supply chain. We work with brands who want to provide their customers with responsibly made clothing that positively impacts people and the planet.

The post Customer Spotlight: Chapman Trading Co. and Magnolia Loom appeared first on TS Designs.

Why Natural Fibers & Dyes Are Key for Apparel Sustainability 17 Oct 2024 6:59 AM (last year)

Eric Henry talks with ASI Media Executive Editor Theresa Hegel

In this episode of Promo Insiders, Henry chats with ASI Media Executive Editor Theresa Hegel about the benefits of natural fibers and dyes and the concept of “apparel manufacturing clusters” as an alternative to global apparel supply chains.

#sustainableapparel #triplebottomline #localmanufacturing #slowfashion #microplastics #ASIMediaPromoInsiders #naturaldyes

The post Why Natural Fibers & Dyes Are Key for Apparel Sustainability appeared first on TS Designs.